Author: Josie

Why should I use ASCO manual transfer switches?

ASCO, manufactured by Schneider Electric, has been using technologies refined by more than 100 years of experience. Founded in 1888, ASCO has prided itself on providing cutting edge technology and never compromising on quality.

The ASCO lines of switches are not cheap knife switches. They use the same type of heavy duty contacts that critical facilities have been relying on for decades. If your application is a critical facility, has heavy motor loads or if you just want the best the ASCO switches are for you.

The ASCO manual transfer switches are suitable for traditional manual switch applications or the can serve to connect the back-up to the back-up generator to comply with new NFPA 70 700 (f) regulations. Check out our post on NFPA 70 700.3 (f) for more information.

FEATURES

ASCO MTS have similar features and options as their automatic transfer switches. Such as, enclosure options and non-SE or SE rated switches.

The 3 position switch on the MTS has a center off position and is pad-lockable. The center off position gives the operator time to allow rotating motors to come to a stop before connecting the other power source causing heavy shocks to the system.

A MTS can have cam-lock connections already integrated into the panel. This option provides a complete UL-listed solution in a single unit and will save on installation costs by reducing the required labor and wiring materials. These models come standard with a NEMA 3R enclosure, with the option to upgrade to a stainless steel housing and uses 16 series Cam-Lok connectors.

You an find all of our available ASCO manual transfer switches here.

End of Life Product Announcement

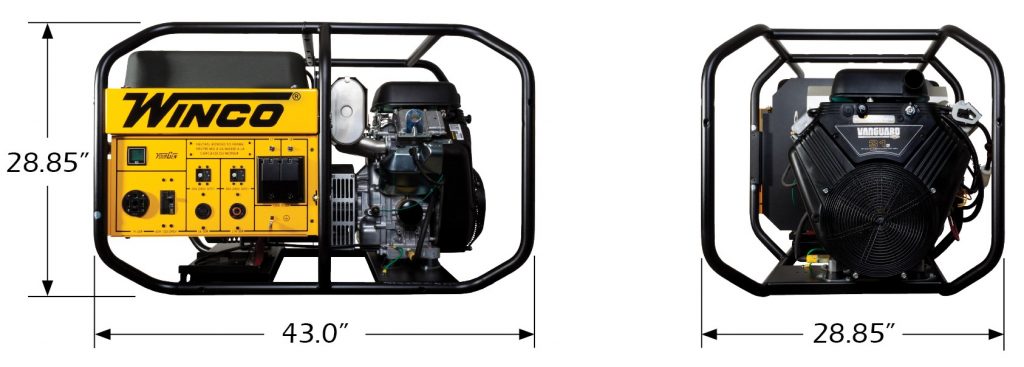

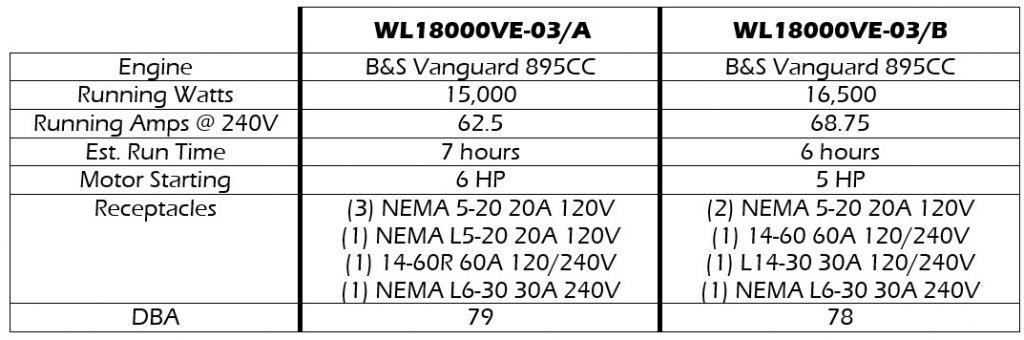

At WINCO, we are constantly engineering and updating out product line! Our latest update is on the WL18000VE. We have redesigned this Big Dog to produce 10% more power. The good news is that even though we increased the power by 10% our engineering and purchasing team have made it possible to sell the new model at the SAME price!

Before we transition to the new WL18000VE/B, we are going to sell out of the previous version first. With the increase in shipments to areas affected by storms we are going to run out of the current model a lot earlier than we anticipated. We anticipate we will run out before the end of September and apologize for the short notice.

Let’s compare the difference between the old and new models:

Click here to get more information and downloads of the new WL18000VE.

– BIG DOG

There’s a new Big Dog in town!

Say hello to the WL16000HE

The newest generator joining our industrial line.

This WL16000HE has all the best components that make our generators stand out! We are a big fan of Honda engines and are excited about the iGX800. Like our other Big Dogs, you get the tough, heavy gauge galvanealed steel, robust receptacle package, industrial generator, all with a 3 year warranty.

We all love more power! The WL16000HE produces 30% more power than our WL12000HE! The receptacle panel has two L6-30 receptacles giving you the capability to run two welders at the same time!

Honda iGX800 Fuel Injected Engine

Easier engine starting

Smoother, more consistent throttle response

Better fuel efficiency

Cleaner exhaust

Better frequency control – Self Tuning Regulator (STR) keeps you right at 60 hz from no load to full load

Click here to get more information and downloads.

– BIG DOG

How do I install a Winco Powr-Pak (open skid) generator?

Some applications require the installation of an open skid generator inside an enclosure. Winco open skid models have some nice features that can make the installation quick and simple.

SIMPLE DUCTING

The radiator divider on your Winco generator comes isolated from the radiator. By installing your ducting right to this sheet metal section and the louvers you can quickly and easily duct the cooling air outside the enclosure. Don’t worry about the muffler, your duct should go right around it. This allows the cooling air from the radiator to push the exhaust heat right out of your structure.

EASIEST EXHAUST PLUMBING

The muffler comes factory mounted and is isolated from the engine vibration. During installation you don’t have to hang the muffler on the roof, install a flex pipe or anything else. Simply hook on to the factory outlet and plumb it out of your building. We used a flex pipe all the way out in our installation.

Since the muffler is located after the radiator you will have a lower ambient temperature making the cooling air for the radiator more effective.

EXHAUST OUTLET

Don’t forget to ensure all of your exhaust outlets do not re-circulate exhaust air into any structure. We include a rain cap so don’t forget to install it to protect your system from water. If you happen to have a laser and want to take it to the next level… check out our exhaust outlet cover!

ISOLATED FUEL SYSTEM

GASEOUS

The fuel inlet will be located on the base of the generator which is vibration isolated from the engine and generator. This can be connected to the generator with rigid piping.

All of our liquid-cooled units are available as an open skid. Click here to see what we have to offer.

For more information on installing a WINCO Powr-Pak generator, you can download the installation manual.